Customised solutions

Strong thermoforming performance for your particular applications

From cups, bowls, lids and clamshell packaging through to plant pots and coffee capsules – whatever you wish to produce, we have the ideal thermoforming solution for every application. The thermoforming systems in our product lines offer their own advantages – depending on the requirements and ambient conditions in production and the product category.

Of course, we will be pleased to advise you directly. Contact us with your questions individually at Thermoform.Sales@gabler.eu

FAQ

Best performance can be reached when your requirements and our solutions are perfectly matched with each other. Our FAQ help you to obtain initial orientation.

Thermoforming production of cups

The production of cups in all sizes and shapes is one of the specialities of our thermoforming machines. Whether you want to produce a cup form in large series or smaller batches with a higher varying factor – we have the right thermoforming machine for you.

Your GABLER advantages

Thermoforming production of lids

Your GABLER advantages

Thermoforming production of bowls of all kinds

Your GABLER advantages

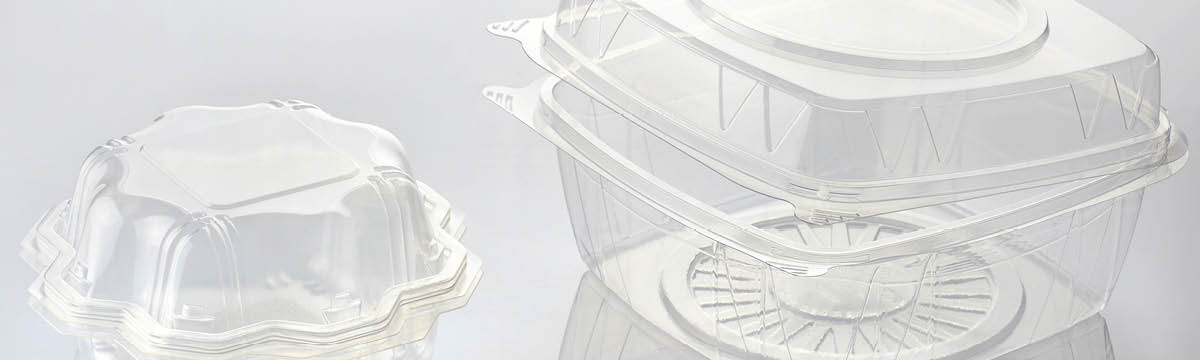

Thermoforming production of clamshell packaging

Our thermoforming systems offer suitable solutions for almost all kinds of clamshell packaging. Depending on your requirements, you can choose machines with separate or combined forming and cutting – with depth of draw of up to 150 mm.

Your GABLER advantages

Thermoforming production of coffee capsules

Coffee capsules go hand in hand with both extreme requirements on precision and constant product quality. Our thermoforming systems make exactly sure of this quality for almost every kind of coffee capsules – either with or without separate perforation.

Your GABLER advantages

Thermoforming production of flower pots