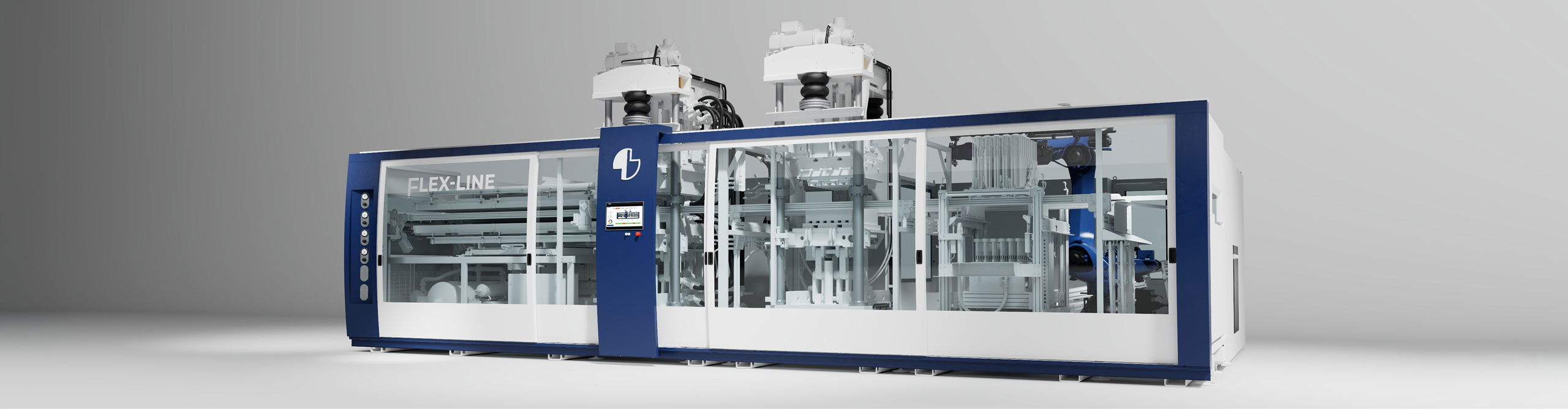

High-end thermoforming automation

GABLER Automation

Boost efficiency, increase productivity, minimise manual complexity: the experts at GABLER Thermoform will support you comprehensively with your targets. Our well-proven approach: based on your targets, we compile proposals for solutions to help you reach these targets. By closely coordinating high-end automation solutions for your thermoforming production that is measurably profitable. Examples:

Seamless material feed

High productivity starts with a non-interrupted input of raw material; seamless transfer to the next foil roll functions with the use of accumulators and foil heat sealers.

Finishing and counting

Quality assurance by camera

You are able to improve your recognition of flaws with automated quality assurance by means of a camera system. You identify material or tool errors in good time – and reduce rejects or complaints.

Automated packaging

Many of our customers attach more and more importance to optimising packaging and logistics. Our high-end solutions, like flow wrappers and packers, reduce manual work and manpower costs in order to save time and money.

Integration of robots

Are you planning to integrate robots in your production line? Our experts assist here, too, by optimally coordinating the thermoforming system and robots to each other. With the aim of perfectly exploiting automation targets for you.