Our understanding how to grow and strengthen a partnership. “Thank you very much for coming to our facility – we appreciate the level of detail and commitment to the service you’ve shown us. You have been there for us when ordering parts, diagnosing problems, programming changes, and more.We appreciate you being available to help us whenever needed. Thanks to your …

“Thank you very much for coming to our facility – we appreciate the level of detail and commitment to the service you’ve shown us. You have been there for us when ordering parts, diagnosing problems, programming changes, and more.We appreciate you being available to help us whenever needed. Thanks to your hard work our machines have been running much better, …

Pieter-Jan Willemse will join Gabler Thermoform as a Sales Area Manager for Benelux

After 20 years in the thermoforming tooling business, Pieter-Jan Willemse has decided that he will continue his sales activities for dexter mould technology as an independent contractor and will also take up the position of sales representative for GABLER Thermoform from May 2022. We are therefore very pleased that he will be supporting us from May onwards with his long-term …

David Schirm is the new Managing Director of GABLER Thermoform

New year, new strategy, new successes. With immediate effect, Gabler Thermoform GmbH & Co. KG will once again be increasingly integrated into the GABLER Group. As of 1 January 2022, David Schirm has replaced our previous Managing Director Jens Kühl and taken over responsibility for GABLER Thermoform. David Schirm has already been managing director of GABLER Maschinenbau GmbH since 2019. …

Automation – driven by speed and hygiene.

Whoever already purchased one or more of our high-class thermoforming equipment knows that we also have a longstanding expertise in fully automated packaging solutions. Our customer centricity and our expertise enable us to engineer and build a fully automated production process line for almost everyone. As demand has increased rapidly in recent years, almost in step with the dramatic increase …

Our new Area Sales Manager for Southeast Asia

We are excited to inform you that from the 1st of January 2021 onwards Matthias Klein will take over the sales activities in Asia. Together with our longstanding and well-known partner Tri Hidayatno, he will ensure an excellent customer service during and after the transition period. Matthias has more than 14 years of experience in the GABLER thermoforming technology, from …

Interview with our new Sales Director North America Christian Kissinger

Why did you decide on GABLER TF?To work with a global leading German technology company in the plastics industry is a great challenge – even more so with the task to continue to establish and grow in the very dynamic NA market. What did you do before?After my studies of mechanical engineering in Kaiserslautern, Germany I put a lot of …

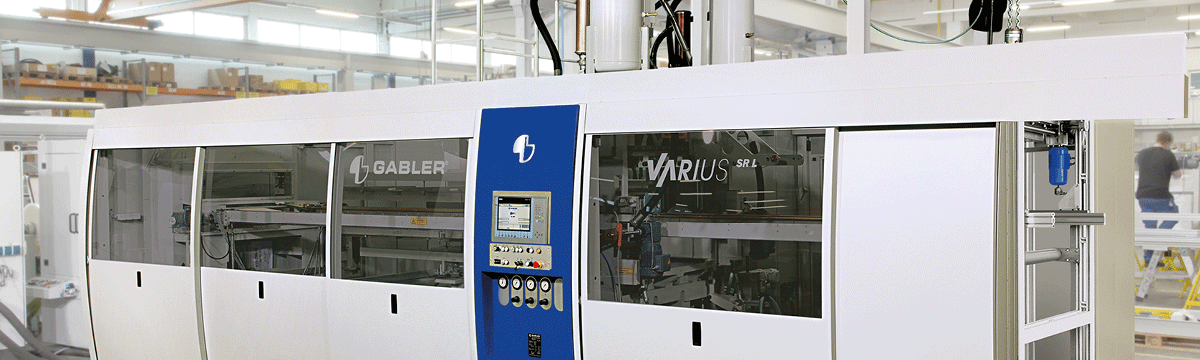

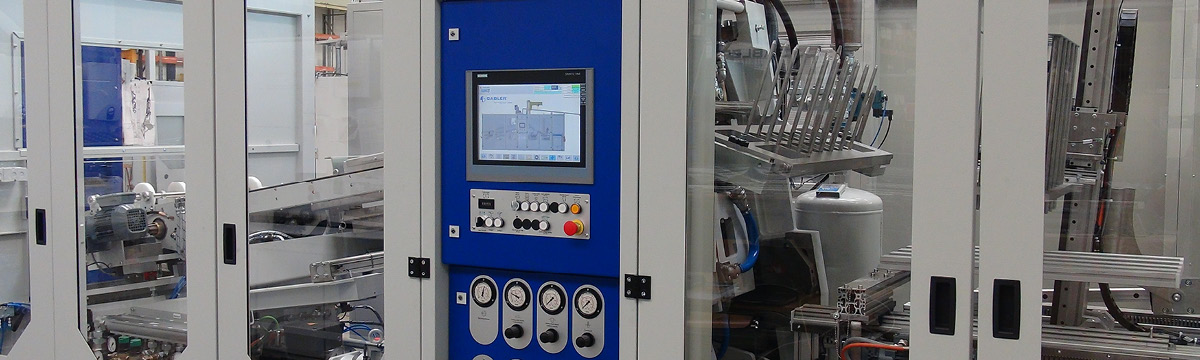

The name says it all: the all-rounder VARIUS

Hardly any other machine offers as many application possibilities as the VARIUS. The thermoforming system with the widest bandwidth can be used flexibly thanks to its three variants – the VARIUS SR for combined forming and punching with steel rule die technology, the VARIUS F as only forming machine with separate punching afterwards and the VARIUS PD for combined forming …

Digital Transformation at Gabler Thermoform – an article in the 07/2020 edition of “Kunststoffe”

The magazine “Kunststoffe” published a three-page article about Gabler Thermoform in its July issue. The article which is entitled “Open control for more efficiency – thermoforming on the way to digital transformation” describes how digitalization has helped increase the performance and efficiency of Gabler Thermoform machines. In this article, the SWING 3 is used as an example to demonstrate the …

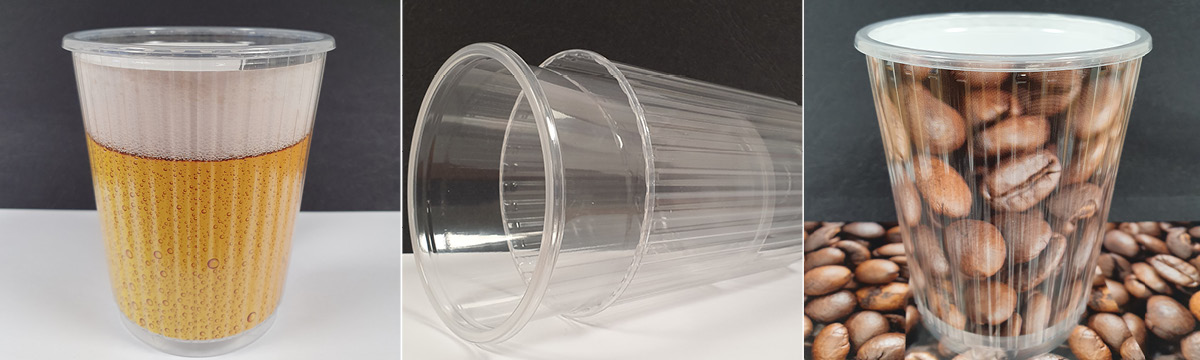

Thermally insulating, flexible and lightweight: the T-Cup

How can you reduce weight and save material with a disposable cup while maintaining the same thermal insulating properties? Gabler Thermoform has found the answer with the top innovative “T-Cup”. The unique design of this double-walled cup consists of an inner and an outer container, which fit together perfectly and are assembled easily. Together, the two cups with a total …

- Page 1 of 2

- 1

- 2