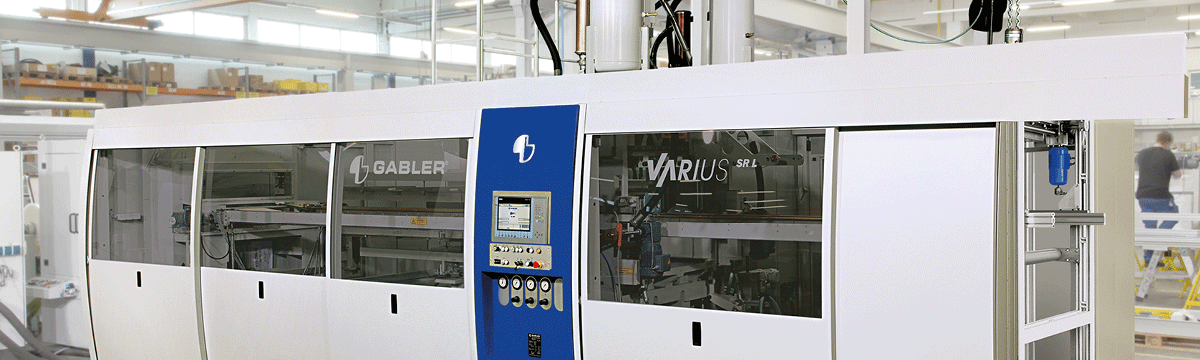

Hardly any other machine offers as many application possibilities as the VARIUS. The thermoforming system with the widest bandwidth can be used flexibly thanks to its three variants – the VARIUS SR for combined forming and punching with steel rule die technology, the VARIUS F as only forming machine with separate punching afterwards and the VARIUS PD for combined forming and match metal punching – has enjoyed great popularity for many years. Due to its continuous further development, the thermoforming line is state-of-the-art technology. Modern measuring and control equipment ensures the greatest possible operating convenience and reliable production processes.

Meat trays of all types and sizes, R108 cups and lids made of PP and PET as well as different types of packaging can be produced quickly and in highest quality with the VARIUS. Its integrated tool-changing system allows a quick and easy changeover to another product. Thanks to a particularly large forming area and adequate cycle rates, the VARIUS achieves a high output rate, making it particularly suitable for use in high-volume production. Due to the cast steel forming station in combination with a fixed upper yoke, the machine also guarantees very high stability and parallelism. This is reflected in high punching forces of up to 85t and long tool life of the cutting parts.

Especially in the past months, when the demand for hygienic packaging was consistently high, the VARIUS was successfully used as a flexible high-performance machine in various projects.

The advantages of the VARIUS at a glance:

- Wide range of applications thanks to three machine variants

- Maximum flexibility for product & requirement changes

- Very high output capacity

- High stability and parallelism

- Maximum ease of operation thanks to state-of-the-art measuring and control equipment